What is 3D printing?

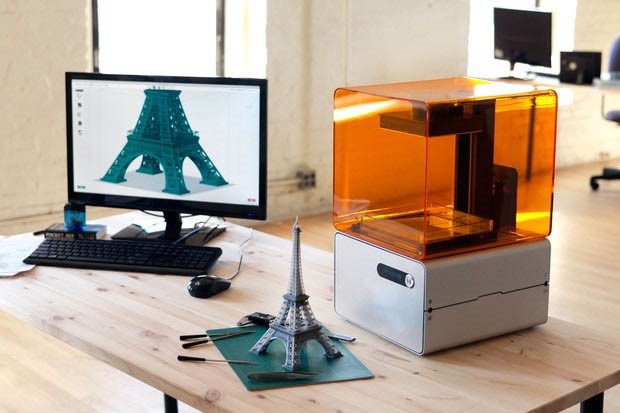

Just like a normal paper printer would work, instead of churning out paper with your printed design on, it prints out materials such as plastic, metal and even concrete to form a pretty impressive three-dimensional object. Instead of the usual method of printing one layer of ink, a 3D printer will print out multiple layers of your desired material and then uses a method of stacking each layer upon each other to form a much more complex object.

3D printing allows us to manufacture many products such as shoes, jewellery, toys, and even furniture, all using a special computer controlled printer. This method of printing is also known as 'additive printing' as the essential rule is that it is an additive manufacturing technique, rather than a subtractive one such as sawing and machining.

This new concept will surely pave the way for brilliantly bespoke designed objects which can be produced on demand for anyone according to their requirements or desires. The technology is so clever that if you have moving parts in your design, the printer will leave gaps in the model, or use a gel that is easy dissolvable or can be washed off after the design is fully printed.

Printing shoes, jewellery and even furniture sounds like something out of a sci-fi movie, but we kid you not, it is the present and the future. So, how does it work, you ask?

As much as we understand it, the 3D printer uses very small and intricate movements to create something.

Most models will print layers which are approximately 100 micrometres thick, but some very high-end machines will print layers as tiny as 16 micrometres thick; to put this in perspective, a typical single bacterium is around 1-10 micrometres in width.

Because of this amazing technology that can be implemented on such a small scale, this has opened doors for using materials such as molecules as ink. This means that some large pharmaceutical companies have now been able to print medicines such as ibuprofen; but the most incredible of all, is that we also make 3D structures out of living cells, this is called 'bio ink'. This creates the unthinkable; being able to print skin tissue, or the ability to reproduce damaged organs. This will eventually cut out the middle man of an organ donor. Instead of waiting for a suitable donor to donate an organ to you, you will be able to just print one. It is astounding to think that this technology is currently being developed and will be available to us in the future.

Depending on which material you intend to use, the colour, resolution, design and budget you have in mind; there are currently five different 3D printing methods to select from. It really is amazing how far technology has come on.

- INKJET PRINTING - This type of printing uses special inks which are called resins and binders and is quite similar to your usual household or office inkjet printer. A 3D model can be created in layers using the resin and binder, where they will keep on adding the layers on top of each other until the model is complete. Currently, this is the only 3D printing method that allows you to have a totally bespoke piece with custom colours.

- FUSED DEPOSITION MODELING - This method is the most popular and common way to print an object. The process for this starts with the raw material which is usually a spool of plastic or metal wire which has been melted and laid down by the printer's nozzle. Once each layer is hardened, the next layer can be added. Commercial printers such as the MakerBot use plastic wire or filament, where the technique is called 'thermoplastic deposition.

- DIGITAL LIGHT PROCESSING - This entails a vat of liquid polymer being transformed into a very strong solid after exposing it to light. This method is done by extremely high accuracy and resolution.

- SELECTIVE LASER SINTERING- The process of sintering creates solid objects from powder, which can be made from metal, glass, ceramic or plastic. What the selective laser sintering then does is pulse a laser which draws the desired cross-section of your desired object. The powder then fuses together and the laser will begin the process again, adding layers on top of one another.

3D printing is certainly the future, and maybe one day, we will be able to print anything we desire in the whole world! Eventually, we might even be able to print a 3 course meal; the possibilities will be endless.